SAFETY FOOTWEAR

Safety Footwear started in 1995 and currently we are producing safety footwear on various constructions such as Direct Injection, PU/PU, PU/TPU, PU/RUBBER, & EVA/RUBBER manufactured by most sophisticated machines imported from Desma Germany and CIC Ralph vulcanized machines from UK.

Our Allen cooper brand is in existence for our two decades in India after craving a niche in International markets. Our premium range consists of water resistant footwear , metal free footwear including a special product range of safety footwear for executives and ladies.

Standard

Premium

Executive

Lady Line

Clean Room

ESR

ESD

Heat Resistant (PU Rubber Sole)

Heat Resistant (DVP NR sole)

Joggers

Sporty Metal Toe

Sporty Metal Free

Sporty Non Leather

Feather Lite

Multi Purpose Boots

Standard

Premium

Executive

Lady Line

Clean Room

ESR

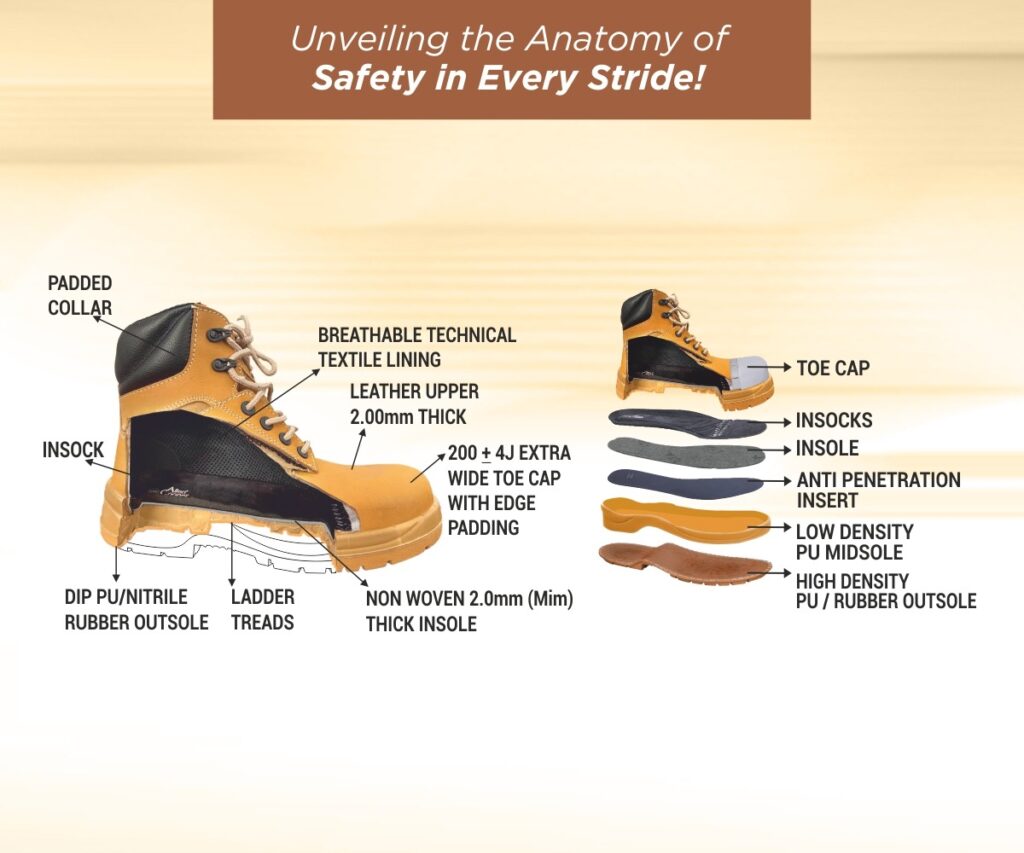

- Genuine Leather Upper

- Breathable Technical Textile Lining

- PC/200±4 J Composite Toe Cap

- Moulded Removable Insocks

- Non- woven Stroble Insole

- DIP PU Double Density Dual color Sole

- Oil, Mild Acid, Slip & Heat Resistant upto 120°C, ESR upto 18KV as per ASTM F2413-05

- Metal Free Shoes

ESD

Heat Resistant (PU Rubber Sole)

Heat Resistant (DVP NR sole)

Joggers

Sporty Metal Toe

- Genuine Leather with Technical Fabric Upper

- Breathable Technical Textile Lining

- 200±4 J Steel Toe Cap

- Moulded Removable Insocks

- Non- woven Stroble Insole

- DIP PU Double Density Dual Color Sole

- Oil, Mild Acid, Slip & Heat Resistant upto 120°C, Antistatic (100 KΩ- 1000MΩ)

Sporty Metal Free

- Genuine Leather with Technical Fabric Upper

- Breathable Technical Textile Lining

- 200±4 J Composite Toe Cap

- Moulded Removable Insocks

- Non- woven Stroble Insole

- DIP PU Triple Density Sole (Popcorn Technology)

- Oil, Mild Acid, Slip & Heat Resistant upto 120°C, Antistatic (100 KΩ- 1000MΩ)

Sporty Non Leather

- Micofiber with Technical Fabric Upper

- Breathable Technical Textile Lining

- 200±4 J Steel Toe Cap

- Moulded Removable Insocks

- Non- woven Stroble Insole

- DIP PU Triple Density Sole (Popcorn Technology)

- Oil, Mild Acid, Slip & Heat Resistant upto 120°C, Antistatic (100 KΩ- 1000MΩ)

Feather Lite

Multi Purpose Boots

- Genuine Leather Upper

- Breathable Technical Textile Lining

- 200±4 J Steel Toe Cap

- Moulded Removable Insocks

- Non- woven Stroble Insole

- Direct Vulcanized Nitrile Rubber Sole

- Oil, Mild Acid, Slip & Heat Resistant upto 300°C, Antistatic (100 KΩ- 1000MΩ), Conductive (<100 KΩ)

Manufacturing Locations

2 units in Unnao

Capacity

15,00,000+ pairs per annum

TECHNOLOGIES AND MATERIALS

- Genuine Leather Upper

-

Microfiber Upper

- Highly Durable Technical Textile Upper

- Breathable Technical Textile Lining

- 200± 4J Metal/Non Metal Toe Cap

- Non Woven Stroble Insole

- Molded Cellulose Board

- Molded Removable Insock made of EVA/PU

- Directly Injected Double Density PU/PU,PU/Rubber & Eva/Rubber

- Direct Vulcanized Rubber Sole

- Design-: Low Ankle/ High Ankle / Full on boots

- ESD-: 100 KΩ- 100 MΩ

- Anti-Static-: 100 KΩ- 1000 MΩ

- Conductive-: <100 KΩ

- ESR-: 18KV for 1 min. ASTM- F2413-05

- Heat Insulation-: <22°C temperature increase on sole after 30 min with 150°C temp of hot plate

- Cold Insulation-: < 10°C temp decrease on the insole after 30min. with temp of (-17±2)°C

- Water Resistance-: <3 cm² wetted area inside the footwear after 80 min of flexing in water tank

- Ankle Protection-: 10KN (mean value) shock absorption capacity when 5kg ± 0.5gm object falling from drop height of 20 cm generating impact energy of 10J.

- Water Penetration-: 0.2gm (max) & 30% (max) after 60 min

- Heat Resistance-: upto 300 °C for 1 min with Nitrile Rubber outsole.

- Nail Penetration-: can resist upto 1100 N

QUALITY CERTIFICATIONS

QUALITY CATEGORIES & STANDARDS

Manufacturing Units are having ISO 9001-2000 and SA 8000 certifications.